Views: 133 Author: Site Editor Publish Time: 2020-08-01 Origin: Site

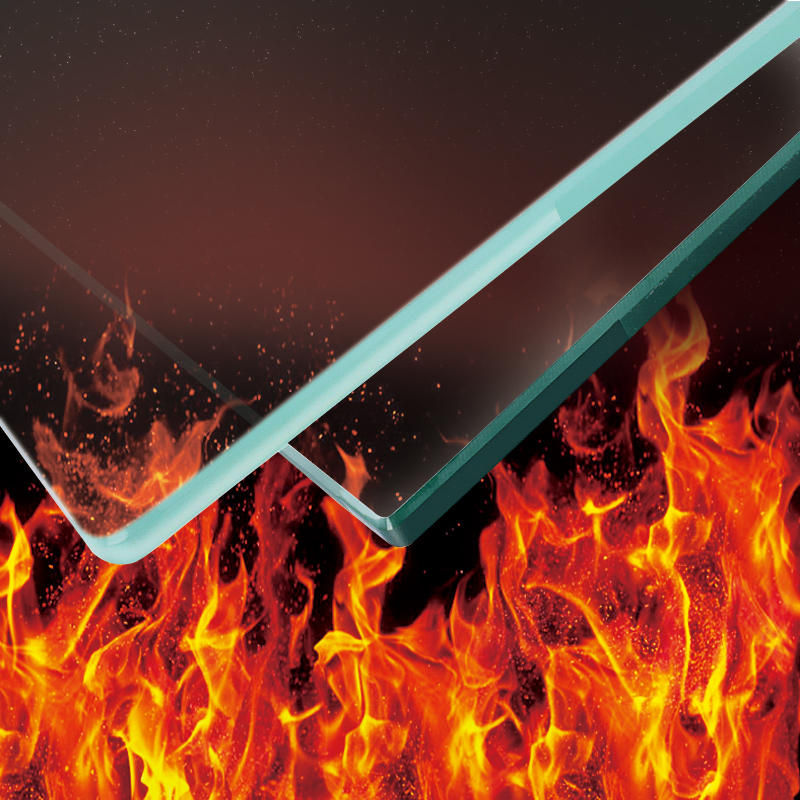

We will start with some basic definitions. What is fireproof glass? As the name suggests, it turns out that this type of glass can provide a certain degree of protection in the event of a fire. For glass, this sounds like a strange task.

Obviously, glass cannot extinguish the fire, nor can it warn the residents of the building of any danger. But fireproof glass can help prevent flames and smoke from spreading from one room to another. The official term is compartment, which means that glass plays a vital role in confining a fire in a limited area.

For casual observers, it seems that any glass can do this. After all, fireproof glass looks similar to non-fireproof glass. However, in reality, most glass provides little fire protection. For example, when the temperature reaches about 250°F, standard window glass will crack.

Tempered glass can be used continuously up to about 500°F. In contrast, fire-resistant glass can usually withstand heat in excess of 1600°F. This is a significant difference in performance. Since structural fires can reach extremely high temperatures very quickly, it is easy to identify the need for this special glass.

In order to obtain stripes, refractory glass must pass a series of tests specified by national standards. Independent laboratories (such as U.L.) run tests and then assign appropriate levels based on the results.

The grade is a time increment, reflecting the duration of testing durable products. This duration is intended to correspond to the length of time that the glass is expected to operate reliably in the fire. Therefore, if the product has a 45-minute rating, in theory, you can expect the product to contain flames and smoke within the first 45 minutes of the fire.

The test is divided into two parts. First, install several pieces of glass on the wall of a large furnace. The walls may contain doors, iron plates, beams, windows, etc. Following a strict time/temperature curve, the heat in the furnace rises to a high level, simulating the situation in a burning building. In order to successfully pass the test, the glass must remain in the frame. If the glass can still act as a barrier to flames and smoke, it is allowed to break.

Assuming that the glass survives the part of the test, a second phase test is required in the United States, with a rated time of 45 minutes or more. This is called the hose flow test and it proves the ability of the glass to withstand thermal shock. Introduce a fire hose with a high-pressure nozzle and immerse it in the hot glass with water at a pressure of at least 30 psi.

Most glass cannot tolerate the pressure of heating one area and cooling another area at the same time, so it will break. If sprinklers are sprinkled in the event of a fire, or firefighters come with fire extinguishers and water pipes, it is very likely that the hot glass will be exposed to water. The last thing anyone wanted to do at that time was to make the glass open an opening, leaving room for flames and smoke to diffuse. The hose flow test can therefore test the integrity of the glass, frame system and surrounding materials.

After the product completes the rigorous testing process, it will receive a fire rating. The score usually ranges from 20 minutes to 3 hours. Then, the building code stipulates the locations in the building where products of different grades are allowed to be used. Generally speaking, the code aims to consider how long it takes for people to leave the building in the event of a fire.

You might suspect that many places that require fireproof glass (such as doors and artificial stones) are also places where impact safety needs to be considered. Due to the very limited product selection, this once caused a real dilemma. Glass with high impact resistance cannot pass the fire test, and the strength of refractory glass (usually wired glass) is not sufficient to achieve minimum impact resistance. Therefore, compromises must usually be made. However, today, several wireless glass products can provide high fire and impact safety.

The impact rating indicates what happens if someone (or something) touches the glass. To test the impact, a 100-pound lead shot bag was placed on a vertical glass plate. For different ratings, the bag will rise to different heights to approximate the effect of personal contact with glass. Then, carefully examine the broken pattern of the glass to determine if it is considered dangerous.

If you see a piece of wired glass with the ANSI Z97.1 mark, it means that the glass has been tested and can withstand a pressure of 100 feet per pound, similar to a child's impact. On the other hand, glass marked as compliant with CPSC 16CFR1201 (Category II) can withstand a pressure of 400 feet per pound. This is similar to the effects of fast-growing adult adults.

After multiplying the number of fire protection levels by the different safety levels, you will find that the possible combinations are impressive. However, ratings alone cannot distinguish the various fire-resistant glasses on the market today. Each product has its unique characteristics, making the decision-making process more complicated.

Despite the wide variety, the field can be organized in a very simple and logical way. All fireproof glass can be divided into the following four main categories:

Polished laminated glass is currently the most famous product in the industry. Used for more than a century, it has a reliable record. Most of the code was originally written around wired glass, because for many years, it was the only glass that passed the fire test. Wired glass was able to pass the hose flow test and received a 45-minute score (even higher on a small door). Regulations and fire officials have been able to immediately recognize the wire mesh as a sign that the glass has been fired.

However, in some cases, the same wire mesh presents an undesirable "institutional" image. Sometimes people mistakenly believe that wire mesh will make glass more resistant to impact. To be honest, laminated glass is a relatively weak glass that can only meet the minimum requirement of 100 feet per pound. Influence standards. With this in mind, even if wired glass is easily available and affordable, you should be careful if you install it in areas where you are concerned about collision safety, such as schools and other high-traffic areas. Some schools that take into account the issue of responsibility, even if the initial cost is high, still use impact-resistant fire-resistant glass.

Ceramic glass is a fire-resistant glass that has entered the market in the past twelve years. For a long time, ceramics have been known for their excellent ability to withstand heat and thermal shock. This is why today you can find ceramics in everything from cooktops to car engines. Once the technology is developed to make transparent products from ceramics, it will soon be possible to see its potential as refractory glass.

Transparent and wireless ceramic glass has obvious aesthetic advantages. It has a variety of cosmetics that can provide many different characteristics: up to 3 hours of fire resistance, high impact safety level, noise reduction, etc. It can also be grooved, etched or sandblasted without affecting the fire resistance level. It even provides insulating glass (IGU) cosmetics that comply with energy regulations for external applications.

Obviously, wireless technology has a fairly modest initial investment. The high impact rating is designed to be suitable for certain door applications. However, it does have some serious serious flaws.

Unlike other fireproof glass products, special tempered glass cannot pass the hose flow test. In an actual fire, if a nearby sprinkler is activated and even a small amount of water hits the hot glass, it is likely to fall out of the frame-most likely this is why it can only meet the 20-minute rating. Many times, this type of material has been replaced with a partial replacement of laminated glass or other higher-performance fire-resistant glass, but it has not reached the same fire-resistant level. If the nozzle is near the opening, consider using this product.

Transparent wall units constitute the last category of fireproof glass, they are a category in themselves. Even if they are made of glass, they have been tested and classified as "openings." They are so famous that they are distorting and burning violently about heat transfer, and you can actually still put your hand on the other side of the glass. Resistance to people who may be trapped in stairwells. Areas, sensitive computer areas or areas using large areas of glass, really need transparent wall panels.

There are different types of these products on the market. Some are insulated units with transparent gel inserted inside, which will turn into opaque foam when on fire. Others are made of multiple layers of glass (equipped with bulletproof glass). Both types of products have a rating of up to 2 hours, can pass the fire hose test and provide a high impact safety level. Thanks to the new frames now available, architects can isolate these transparent wall and door units from floor to ceiling in their design and still provide 2 hours of fire protection.

| | NO 1506, XINYE ROAD, SHAPING TOWN, HESHAN CITY, JIANGMEN, GUANGDONG, CHINA |

| | +8613750315014 |

| |